Why Do We Need to Batch Produce and use Batch Numbers?

A batch, according to the US FDA, means a specific quantity of a drug or other material that is intended to have uniform character and quality, within specified limits, and is produced according to a single manufacturing order during the same cycle of manufacture. A batch therefore is a specific amount of an API or other material that is processed in one or more ways so as to demonstrate homogeneity of the product.

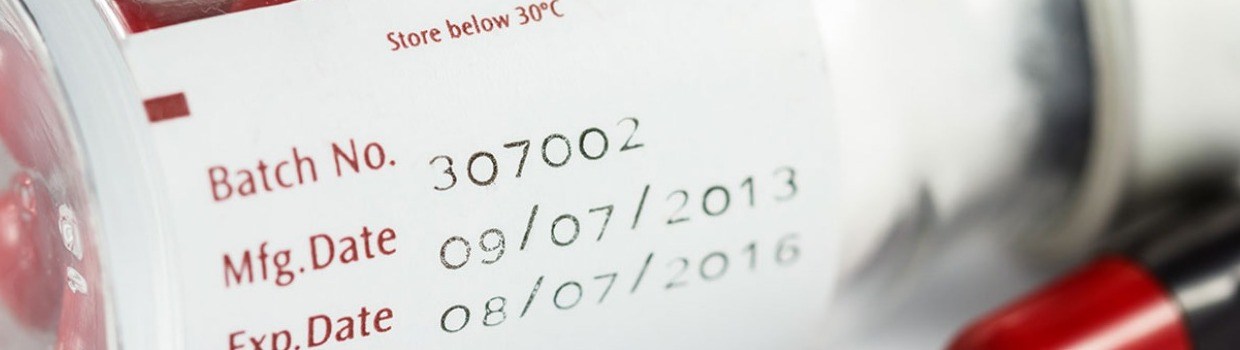

Batch Number

A batch number is a designation that is printed on the drug label that allows the history of its production to be traced. This includes not only identification of the specific batch produced, but all relevant issues of control and manufacturing particulars should also be traceable from the batch number.

It is important therefore that all batches of tablets are given an identifying number immediately after production from the rotary tablet press (or any type of pill press) or capsule filler and before progressing to the packaging stage.

Suscríbase a nuestro boletín de noticias

Importance of the Batch Number for Pharmaceutical Companies

Batch number is also referred to as “lot number”. Recording of the batch and batch number typically starts at the manufacturing plant. Batches should be maintained and recorded according to:

- Quantity

- Manufacturing cycle

- Expiry date

- Weight of the active ingredient

- Excipient(s)

The importance of the batch is best understood from drugs that are manufactured in New Zealand. According to the code of conduct of the New Zealand Ministry of Health with regards to drug manufacturing, should there be any cause for concern with a drug, its complete production history must be able to be traced back through the batch number. The New Zealand legislation requires plant operators to measure the amount of active ingredients used in any one batch and to enter this as part of the record of the batch. In the manufacturing plant, the operator will therefore produce a different batch record for each medicine or drug that is prepared and for each batch that is produced. The batch record is documented and provides the legal evidence that the manufacturing process complies with the regulatory guidelines. The record must show the product formula and the steps needed to prepare the product.

According to the regulatory guidelines, each drug batch is provided with a unique identifying number that is written on the batch documentation. The specified batch is then used to identify all the steps in the production process and should also be printed on the labels clearly at the end of the manufacturing process, e.g., during packaging. A sample of each batch of product is then kept for shelf-life plus a year. When the production of one lot or a batch of a drug is completed then all equipment must be sanitized and cleaned as required by the regulatory guidelines. Sanitization is carried out to prevent any contamination that may occur when starting the preparation or production of a new drug. The QA department should carry out checks to test if the equipment meets the required standards of cleanliness.

The exact lot or batch number on behalf of which, one can check the entire manufacturing history during that time. One can check the expiry and manufacturing date. The prices of the specified batch can be checked.

Importance of the Batch Number for the Ministry of Health

The lot number or batch number is important and should be place on the bottles, packs and cartons as specified by the country’s Ministry of Health. The number is important as it may be required especially in the case of when a vaccine or capsule is recalled, or there is a failure with regards to the quality of the batch.