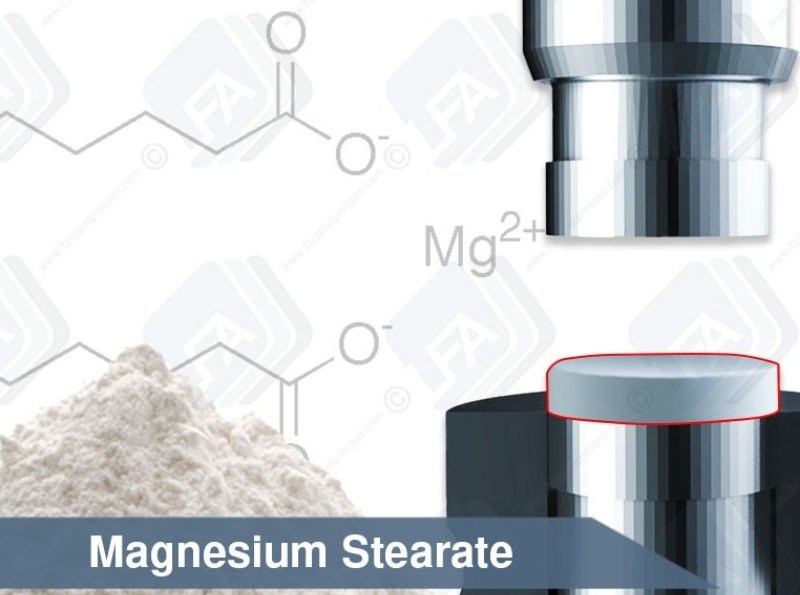

ステアリン酸マグネシウムは、白色の微粉末です。その主な目的は、カプセルや錠剤の潤滑性を提供することです。流動性を高め、製造プロセスを通して効率性を確保します。

ステアリン酸マグネシウムは、業界で最も人気のある流動化剤のうちの1つです。乾燥被膜潤滑剤としてその効率性に人気があります。ステアリン酸マグネシウムは不活性で、製剤化工程をずっとスムーズにすることができます。

ステアリン酸マグネシウムは、ステアリン酸うぃ含むマグネシウムです。ステアリン酸は、食品でよく見られる炭素数18の飽和脂肪酸です。ステアリンは、動物から野菜まですべての単一種類の脂肪です。それは、魚類、豆類、卵、バター、鳥肉、食肉や酪農製品によくある脂肪酸です。食肉の場合、飽和脂肪の1/3です。これは消費者の親密度にとって重要です。また、この成分の安全性を表します。人体にとって新しいものではありません。ステアリン酸マグネシウムは、製品に安全な要素を与えます。

潤滑剤を使用する理由

潤滑剤は錠剤化にとって極めて重要です。これは、ステアリン酸マグネシウムが一般的に使用されているということです。潤滑剤の目的は、特定のプロセスのメリットを高めることです。潤滑剤には3つの役割があります。

放出する時に錠剤表面とダイ壁間の接点で摩擦を減少させる。これは錠剤の破損を減らします。

作動している機械に癒着するのを防ぐ。

粒子同士の摩擦を減少させることで流れを良くする。

優れた潤滑剤は、表面全体に強い皮膜を作ります。もうひとつのプラスの要因は、プロセス変数における変化に反することです。これは、一般的に流動性、圧力や温度になります。これらのうちどれかが変化する場合、製造プロセスへ影響を与えてはなりません。

マグネシウムは健康にとって重要です。必須ミネラルとして、それを見つけられる場所が多いにもかかわらず、人間の食事からよく見過ごされます。マグネシウムは、血糖や血圧を適正レベルに保ちます。DNAやタンパク質を形成するのを助け、筋肉や神経を正しく機能させるのに役立ちます。良好な健康を目指すのであれば、男性は1日あたり420㎎必要で、女性は1日あたり320㎎必要です。

ステアリン酸マグネシウム...:

"GRAS" (食品医薬品局合格証) に登録

欧州では食品添加物に指定されている。

植物油(多くの場合、パーム油や綿実油)から作られる。

ステアリン酸マグネシウムの取り扱い

ステアリン酸は、水素化(水素で処理)から作ることができます。このプロセスの結果は、適切に処理されなければならない製品です。

ステアリン酸マグネシウムは、粉塵爆発が起きる可能性があるので空気と混合できません。費用がいくらかかっても、炎から遠ざけなければなりません。乾燥状態の場合、他の行為の間に回転させ注ぐことによって静電気的に帯電させることができます。空気感染したらは咳を引き起こし、摂取すると嘔吐が起きる恐れがあります。本製品を取り扱う間は、保護グローブ、安全ゴーグルやマスクを使用しましょう。

ステアリン酸マグネシウムの化学式はMg(C18H35O2)です。ステアリン酸マグネシウムの別名は、オクタデカン酸やマグネシウム塩です。

本製品は、乾燥潤滑剤として一般的に選ばれます。さらに、身体が安心できるミネラルとして、定期的に安全に摂取することができます。お客様の製品にふさわしい賦形剤になるでしょう。

Are all excipients safe for all ages to consume?

Yes, it does not matter what age, size or sex the person consuming the products is. It is, however, important to check the intolerance data.

Are all the excipients safe for human consumption?

Yes, all of the excipients are safe for human or animal consumption. There are some precautions that should be taken when handling them and there are some people that might have intolerances to some of them. Information on this can be found in the products MSDS and Intolerance Data Sheet. This can be found in this section for every excipient.

Are your Excipients natural?

Yes, all of our Excipients are extracted from natural sources. For more information please visit the individual product pages.

Can I get a better price for excipients than is listed on the website?

Yes, we have bulk pricing for all of our excipients, and these can be found in this section. We offer bulk in 500 kg, 1 ton, 2 ton and 5 ton lots. The prices are set on these quantities as these are the amounts that will fit on pallets.

Can I have a CoA for my Excipient?

Yes. CoA stands for Certificate of Analysis this is also known some times as an MSDS (Material Safety Data Sheet) all of the information contained in a CoA is inside the MSDS for every LFA product which is emailed to you after purchase.

Can I produce tablets without Excipients?

It is unlikely that you will be able to produce tablets without using any Excipients at all. Certain products do bind without Excipients, but then do not flow through the machine. We advise that you use our Firmapress ready mix as this works with 99% of products.

Dissolving rate? Any known factors that can affect the rate, speed up or slow down the breakdown of a tablet?

Yes. There are two things at play here. You can get hygroscopic and hydrophobic excipients. Hygroscopic means that they take on water quickly, while hydrophobic means that they repel water.

There are products know as supper disintegrants. These products help the breakdown of tablets. At the moment LFA does not sell any supper disintegrants.

Magnesium stearate is hydrophobic this means that it will slow the breakdown of a tablet.

However, it is used in such small amounts that most of the time it will not make a difference to our customer's products. If they would like to be sure then they should conduct what is known as a disintegration test.

How long is the storage period of each excipient? What is the shelf life?

Firmapress - 2 years form batch date.

Dextrose - 3 years from batch date.

Dicalcium Phosphate - 3 years from batch date.

Microcrystalline Cellulose -

Magnesium stearate -

Lactose - 2 years from batch date.

Silica Dioxide - 2 years from batch date.

How should I clean contact parts that have come into contact with my excipients or active ingredients?

here are 6 steps that should be followed as a general rule of thumb when cleaning contact surfaces that have come into contact with powders:

Dry Clean - First you need to remove as much of the dry powder as possible. You can do this using a hover/vacuum. Make sure that the vacuum you are using has a filter good enough to handle fine dust.

Wet Clean - Next you need to perform a wet clean. This can be done with warm water and soap or if available an ultrasonic cleaner.

Rinse - Next you need to rinse off any soap with potable water (drinking water). You do not have to do this if you used an ultrasonic cleaner in the last step. It is important to ensure that all parts are thoroughly dried immediately after washing to avoid any rusting.

Sanitise - Next you need to sanitise the surface. This step is recommended by the FDA. There are a number of sanitising solutions available designed to be applied and left on.

Lubricate - You now need to lubricate any parts that require it. This should be with the appropriate grade oil or grease considering your use and greasing chart. Store - Finally store any of the parts in a cool dry place. If you are storing them on the machine then make sure the machine is in a temperature controlled environment with low humidity.

What is the difference between the range of excipients?

We offer Microcrystalline Cellulose, Magnesium Stearate, Dicalcium Phosphate and Firmapress in our range of excipients.

Microcrystalline Cellulose is a binding agent, which holds the content of the tablet together.

Dicalcium Phosphate is a flowing agent and helps move ingredients through the machine before they are compressed.

Magnesium Stearate is a dry lubricant and helps again with the movement of ingredients through the machine but also helps with the ejection of the tablets from the machine. Please note that Magnesium Sterate does not bind by itself.

Firmapress is an all in one mix of Microcrystalline Cellulose, Magnesium Stearate and Dicalcium Phosphate.

What is the mesh size of your excipients? etc.

Dextrose - approx 100 mesh

Dicalcium Phosphate - approx 100 mesh

Microcrystoline Cellulose - approx 120-200

Magnesium sterate -

Lactose - 80 mesh

Silica Dioxide -

Firmapress - 100-200 mesh

What kind of agent is each excipient?/ What is the main use of each excipient?

Dextrose - Sweetener, binding agent, good for chewable tablets or candy.

Microcrystalline Cellulose - Binder, filling agent. Good at binding tablets and making them bigger. It can also be used as a filler for capsules.

Magnesium stearate - Dry Lubricant. This stops products from getting stuck to the tooling. It can also help with powder flow issues and caking issues.

Lactose - Binder, sweetener and bulking agent. It has a large mesh so it flows well but most people do not like it because of the intolerance issues.

Silica Dioxide - Flowing agent. This assist powders in flowing smoothly through the machines. It also helps with cacking issues where powders get stuck to the machine.

What kind of condition should excipients be stored in?

Firmapress - 2 years form batch date.

Dextrose - 3 years from batch date.

Dicalcium Phosphate - 3 years from batch date.

Microcrystalline Cellulose -

Magnesium stearate -

Lactose - 2 years from batch date.

Silica Dioxide - 2 years from batch date.

Which excipient should I add if the product doesn't bind well?

If your product does not bind well then we would recommend using MCC. This can be used in any % the limiting factor is the size of the tablet.

If the amount of MCC you would have to use would be too much or if you do not want to use MCC then you have 3 other options: Ask your supplier for a directly compressible or tabletable grade of your product. Spray dry your product. Wet granulate your product.

Which excipient should I add if the product is sticky?

If your product is sticky then you will need to add a dry lubricant to your mix. For this, we recommend magnesium stearate.

We do not recommend that you add more than 1% to the mix as more than this can cause capping. If your product is still sticky at this point then we would recommend looking into granulation.

Which excipient should I add if the product/API is clumpy?

If your product or API is clumpy then you will need to add an anticaking agent. For this, we recommend silicon dioxide. We only recommend adding a maximum of 2% of this to the mix