有些人想自己在家压片,但商业压片机的价格让他们望而却步,VICE压片机改变了这一格局,是全新概念的设备。

事实上,VICE压片机改变了所有压片机应用场景的游戏规则。无论你是想为自己制作补品的个人,还是需要制作少量片剂用于研发的商业组织,这种创新式的压片机都能助你一臂之力。

VICE 压片机的主要优势

- 2分钟内压出你想要的片剂。

- 不锈钢和阳极氧化铝机身,坚固耐用,重量轻。

- 使用安全,完全符合GMP规范。

- 能够生产直径为2mm到22mm的片剂或丸剂。

- 赠送6mm/8mm/10mm三种尺寸的冲模。

- 方便安装标准TDP5压片机冲模,尺寸和形状有更多选择。

- 定制冲模也很容易

- 20千牛压力,生产医药级的片剂,不碎片,不粗糙。

- 多种颜色可选,美观吸睛。

- 赠送全套清洁套装。

- 提供彩色VICE粉料,各种粘合剂,确保片剂专业美观、质量优异。

- 终身保修。

特点:

VICE手动压片机由于简单易用、价格低廉、构造结实、小巧轻便,在众多压片设备中脱颖而出。它拥有光滑的阳极氧化铝机身,未来感十足的线条,美得像一个时尚配件。但它又是一款实用高效的机器,让压片变得前所未有之容易。

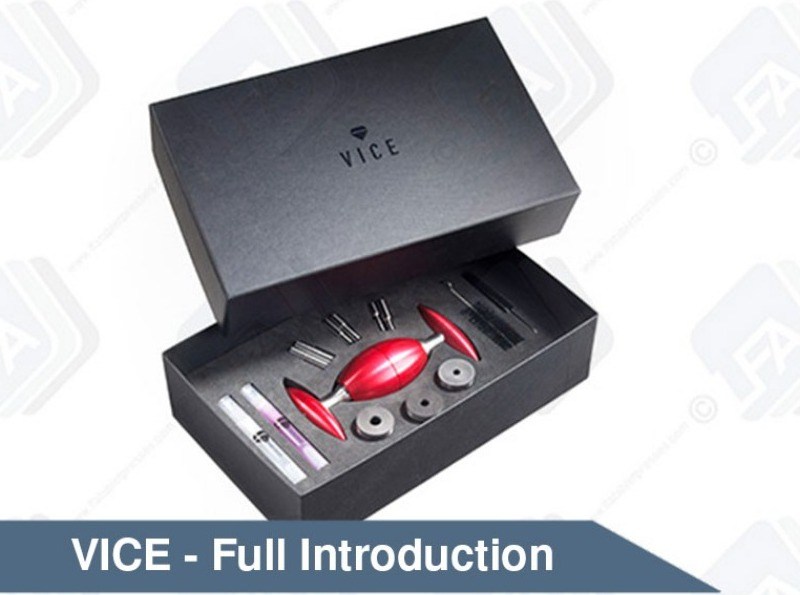

购买VICE手动压片机将赠送全套压片配件,包括6mm、8mm和10mm三种尺寸的冲模,综合性的清洁套装以保持压片机处于最优状态,还有通俗易懂的说明书。VICE手动压片机可塑性很强。你可以迅速更换冲模,生产从直径2mm到22mm的任何尺寸的片剂。VICE不仅只制作圆片,更换冲模后,你可以制作任何形状的片剂。

VICE压片机的设计团队明白,评判任何一款压片机最重要的标准是压出来的片剂的质量。这正是VICE压片机出色的地方,它拥有制造精良的螺纹,最大压力可达20千牛,只要一点力气就能压出优质片剂。不管在什么地方,任何人都能利用VICE压片机在短时间内生产出完美的片剂。

设计团队还着重考虑VICE压片机的重量,不锈钢和阳极氧化铝机身超级坚实,但也足够轻便,方便搬移。VICE压片机拥有长久的使用寿命,您可以放心,它能为您服务数年。

该机器还方便维护和清洁,专用清洁套装含有刷子、润滑剂和清洁材料,让您的压片机处于完美的状态。

VICE压片机的使用

VICE压片机最明显的优势是它不需要电力。这款压片机使用很简单,压力通过冲模轻松传导,压出片剂。冲模可以任意更换。VICE压片机功能多样。它不仅可以兼容各种各样的冲模,你还可以定制配件,拥有无限选择。VICE压片机作为一款革新式的设备,为它定制配件异常简单。

使用VICE压片机,不会出现碎片或松片的情况,你得到的将是光滑、紧密、有型的片剂,看起来就像制药包装线上的药片一样。VICE压片机能生产直径22mm的片剂,也就是说,你可以将多种材料混合到一起,所以这款机器非常适合生产类似钙片这样的需要大量材料的补充剂。您将获得含有所有赋形剂和粘合剂在内的混合粉料,可以方便您生产任何种类的片剂。

我们的观点

VICE压片机是真正的突破性产品,价格低、使用方便。有史以来第一次,普通消费者也能快速轻松的制作顶级质量的片剂,而且不需要花很多钱。

它多功能、易于使用,只需极少的维护让它保持干净。对于追求成本效益、追求快速简单的压片的应用场景,VICE压片机是极其具有吸引力的完美解决方案。

Can I change the 3 sets of free tooling that are included with the VICE?

Sorry, but we are not able to customize the tooling that is included with the VICE.

However, supplementary tooling can be ordered at an additional cost if required: TDP Tooling | Punch & Dies for TDP Pill Presses

Can I get support from LFA if I face problems with making tablets?

Yes. Very easily.

We have free lifetime technical support for all machines sold by LFA.

Just contact us with your machine serial number and we would be happy to help you with any problems.

Can I order custom tooling?

Yes. You can order custom tooling here

Can I put my VICE in an autoclave?

Yes, the tooling is S7 steel, the body is aluminium, and the threads on the handles are both SS 304 steel. The entire device can withstand 120°C (248°F) in an autoclave for 20-30 mins.

Do all TDPs and the VICE take the same tooling?

It is important to know two things:

Firstly, TDP Universal Tooling came into effect in 2018. Machines brought from LFA before this time may be slightly different sizes. We always recommend checking the size of your tooling before placing your order.

Secondly, a number of companies make unofficial TDP tablet presses.

They do not always conform to the same sizes, tolerance or quality as LFA TDPs or tooling. If you bought your press from someone else other than LFA, we are not able to guarantee that our tooling will fit.

Do I need a license to own this machine?

That depends on the country you are located in.

In the EU and UK no. You do not need anything to buy the press.

In the USA we have to file a piece of paperwork with the federal government when we sell the press.

We, however, do all of this paperwork for you and do not need to do anything.

The only countries that require a license, as far as we know, are Canada and Australia.

If you are located in Canada then we recommend that you contact Health Canada prior to placing your order. Details regarding the import process can be found at the following link: Importing and registering pill presses (designated devices)

The document you need to fill out and file for a purchase originating in Australia is called a B712. This can be found at: https://www.abf.gov.au/form-listing/forms/b712.pdf. If you would like to speak with one of our team about this, then please get in contact.

Does this machine come with free training?

Yes, we offer free training at your local LFA office. For a list of our office addresses, see here. Training is normally completed in less than one day, but please get in touch for more information.

How can I set the weight when using a VICE?

On the VICE there is a technique to "set" the weight. You can do this by marking the location of the lower pin, which will allow you to fill it volumetrically. To do this:

First, weigh out the amount of powder you need in a tablet.

Next, wind the lower pin all the way until it is at the lowest position.

Now, fill the die cavity with the weighed out powder.

Then, raise the lower pin until the powder is flush with the top of the die cavity and about to overflow.

Finally, mark off the position of the threads on the lower pin handle. All you will need to do is return it to the same position and fill it with a mix of the same density to make tablets of the same weight.

How do you clean the VICE efficiently? Are there any special products that you recommend?

The process of cleaning a VICE is fairly simple.

First, remove all of the powder from your VICE.

Next, rinse the VICE with warm water.

Finally, make sure that it is completely dry before applying oil to stop corrosion.

Here is a more detailed video on how to clean your VICE: How to Clean your VICE Handheld Tablet Pill Press | Video

The VICE press comes with a cleaner and a food grade oil. We recommend using both of these to clean and lubricate your device.

How many tablets can the VICE make per minute/hour?

This will depend on the user. There are a number of things that you can do to make it as efficient as possible:

Make a tablet pre-mix with your active ingredients and all of the excipients you need. We recommend using Firmapress for your excipient since it acts as both a binder and flow agent.

We also have videos and a tablet mix calculator to help you calculate the ratio of active ingredients to excipients needed to make a tablet.

Tablet Mix Calculator | Free Tool to Help Pill Formulation

Making a Tablet Pill Mix - Making a Test Mix

Next, set up on a tray or a clean and flat surface. This will help you recover any lost powders.

You will also need a high accuracy scale to weigh your tablets.

Finally, marking off the position of the threads on the lower pin handle will allow you to make tablets that are the same size with each run.

With all of these items in place, we find that we can make approximately 2-3 tablets per minute or 120-180 per hour. This depends, on your practice, the size of the tablet and how much force you apply.

How many tablets can VICE produce before you have to replace it?

Infinite, the design of the press is incredibly robust. If you do manage to break it, contact your local LFA office.

While we cannot guarantee the machine for life, we would be happy to inspect the machine to determine if there were any manufacturing defects. Should this be the case a replacement would be considered.

How much is too much pressure on the VICE handheld press?

If too much pressure is applied to the VICE, it will jam shut. If this happens, you will need to remove the handles from each end using an Allen key or hex key set. Then, using two large wrenches on each end, unjam the device.

Is the VICE GMP approved?

It depends on your location as every country has a different set of rules to define GMP compliance. However, LFA VICE Press is an extremely simple item that is made completely out of parts that are washable. It has two main components made from aluminium and stainless steel parts. We believe that our VICE is GMP compliant under all GMP guidelines. We do however recommend checking your local regulations if you are unsure.

The dies have become discoloured. Is this because of corrosion?

Yes, this could be down to corrosion or due to oxidation of your product. We would highly recommend taking your tooling out of the press and cleaning it at the end of every production run.

We would also recommend polishing the tooling to keep the surfaces clean and less likely to cause picking or capping.

The tablets I am making with the VICE are coming out soft and do not retain their structure, even when using excipients. They fall apart with just the slightest touch/pressure. What should I do?

The VICE exerts about 21 kN of pressure, which is more than enough to make a tablet. If the tablet falls apart, either the device needs to be screwed tighter or the formula needs to be adjusted.

What is the maximum pressure I can achieve with a VICE?

The average max force a VICE can produce is 21kN. The pressure depends on the force the user is able to apply to the machine handles.

What is the VICE Handheld Press made of?

The VICE is made of aluminium and stainless steel. The TDP Tooling that is included with the VICE is made of S7 steel.

What should we do if we don't want to use any excipients, especially binders?

When using VICE to make a tablet should I wait to let the tablet set in the press to increase its hardness?

You can, if you like, let the press sit for 5-10 mins. This is what is called dwell time. It helps sometimes, but most of the time this is far too long.

Where is this machine made and shipped from?

All of our machines are made by us in Taiwan, and are shipped to you from our nearest office.

We have offices in the UK, USA, Germany and Taiwan.

Because they are made by us, we are able to control quality and give you the best support possible. And because they are shipped from your local office, wait times are reduced and customs clearance is avoided, ensuring you have support in your time zone in a language that is convenient to you.